HOME > Product Info > Material

High Melting Point Material

≫ Press button to go to the desire page.

Tungsten

Main Properties

Tungsten has 99.75-99.99 product purity for commercial sale. Tungsten is known for its robustness. Has a highest melting point of all pure metal. It has a high density than water and second only to carbon. Tunsten has 2 forms A form and Bform. The A Form is the most stable form but the Beta form has a spontaneous combustion instability.

Due to Tungsten’s strength at high temperature and its high melting point, it is used in many high temperature application.

Applications

Pure tungsten incandescent filament of a vacuum tube, welding electrodes, electrical contacts are used in the electric field. Mainly in the manufacture of alloys, such as tungsten steel, high speed steel while Carbide is very hard and is only applicable to machine tools.

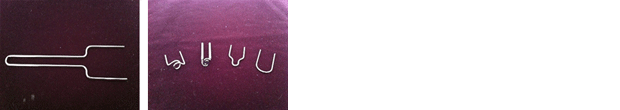

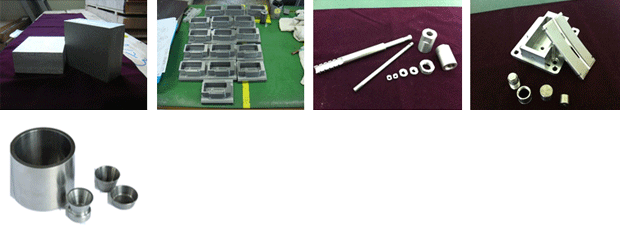

Product Image

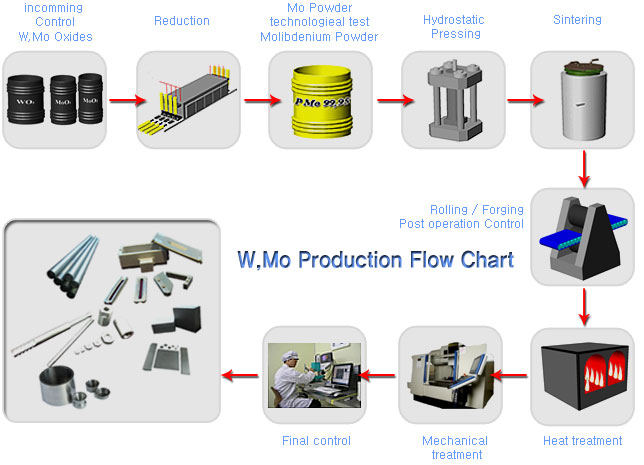

Molybdenum

Main Properties

The ability of Molybdenum to withstand extreme temperature without expanding and softening makes it useful application that involves intense heat which includes the manufacture of armor ,aircraft parts, electrical contracts, industrial motors and filaments.

Commonly used high strength steel alloys contains Molybdenum. Even in small portions, Molybdenum are used as an alloying agent in stainless steel, tool steel, cast iron and high temperature alloys.

Because of its lower density and more stable price, Molybdenum is sometimes used instead of Tungsten.

Applications

High temperature-resistant Pole, is widely used in the manufacture of aircraft materials, electrical contacts, industrial motors, and filaments. Commonly used strong internal metalS such as alloy, stainless steel, tool steel, cast iron, are used instead of tungsten due to its lower density and more stable price. Also used as flame retardant coating for other metals.

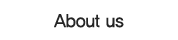

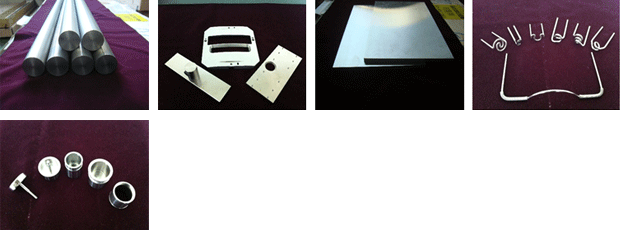

Product Image

Tantalum

Main Properties

Similar to platinum, Tantalum is a highly corrosion resistant-rare hard blue gray metal. Has a chemical symbol of TA with a Specific gravity of 6.5 and a melting point of 2850 degree Celsius.Tantalum exist in crystalline phases Alpha and Beta. Alpha phase is ductile and soft and Beta Phase is hard and brittle. Tanthalum when heated to high temperature is vulnerable to gas absorption of 1700 degree Celsius.

Tantalum is used to produce alloys with high melting points and are strong with good ductility. Tantalum is also widely used in making surgical apparatus and implants.

Purity of a commercially sold Tantalum Carbide is 99.8% and the highest melting point is 38.75 degree Celsius.

Applications

Is used for nose of bulb frontline, crucibles, electrode, and heat resistant steel additives.

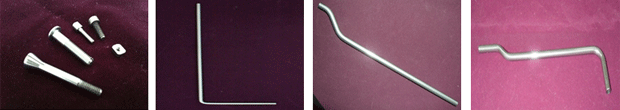

Product Image

Boron Nitride

Main Properties

Boron Nitride is a good electrical insulator. It has very high thermal conductivity and good thermal shock resistance. BN is stable in inert and reducing atmosphere up to 2800 and in oxidizing atmosphere of up to 850.

BN is a synthetic material .It is a combination of boron and nitrogen. Boron Nitride is achieve by nitradation or ammonalysis of boric oxide at elevated temperature.

Applications

In the chemical absence of heat-resistant and high-temperature insulation material (insulator) refractory corrosion-resistant metallic member (melting crucible) and those with Boron impurities.

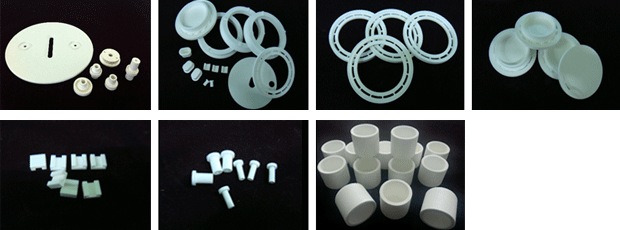

Product Image

TZM

Main Properties

Molybdenum's prime alloy is TZM. This alloy contains 99.2% min. to 99.5% max. of Mo, 0.50% Ti and 0.08% Zr with a trace of C for carbide formations. TZM offers twice the strength of pure moly at temperatures over 1300'C. The recrystallization temperature of TZM is approximately 250'C higher than moly and it offers better weldability.

High-temperature strength of Mo increases when a small amount of C is added, but the composition is not good. So, with a combination of strong carbide-generated elements such as Ti, Zr, these stable carbides dispersed in the possession of the organization, and when forged improves its strength . Ductility at room temperature of the high melting point alloy TZM is the most practical, very strong, and a requires a small amount of alloying . TZC, increases the concentration of alloying elements and less than this will improve the strength and poor ductility and enhanced 25% W alloy WZ vulnerability. Ductile Mo alloy at 0 ° C or less, only the Mo-50% Re alloy.

TZM alloy (1.2at% Ti, 1.7at% Nb, Zr 0.3at%, 0.5at% C, the remaining Mo) 10-7-sec-1 at 1315 ° C. The creep strength of TZM alloy is 14 kg of F / ㎟ It is about 27 kg f / mm 2.

0.5at%, lower transition temperature is obtained using the precipitation HFCs Mo strength creeps above Mo-HC Alloys (0.6at% Hf, C) in the 26 kg f / ㎟ Mo-alloy RHC (2at% Re, Hf 0.7at%, 0.5at% C) in the 29 ㎏ the f / ㎟ amounts.

Applications

High temperature-resistant Pole , is widely used in the manufacture of aircraft materials, electrical contacts, industrial motors, and filaments. Commonly used strong internal metalS such as alloy, stainless steel, tool steel, cast iron, are used instead of tungsten due to its lower density and more stable price. Also used as flame retardant coating for other metals.

Product Image

Rhenium

Main Properties

Rhenium is a silvery-white metal with one of the highest melting points of all elements, the powder is flammable once heated and oxidized at above 100 degree celsius.

The powder form is easily oxidized by nitric acid, hydrogen peroxide and chlorine. Acid oxidation responds to rosen sulfur and dissolves slowly to nitric acid and sulfuric acid.

Has the same chemical properties similar to Tungsten, Technetium and Molybdenum.

Applications

Less costly and yield a lot, but not commonly used because of the size of the thermionic emission in the manufacture of electron tubes. • Platinum additives • Due to various decomposition reaction Acetylene Hydrogenation carbon monoxide and hydrogen are used as a catalyst, but is limited to Fountain pen nib, high-temperature thermoelectric pairs (with platinum), electrical components, such as the electrical contact and mechanical support points , rhenium and rhenium metal alloy.

Product Image